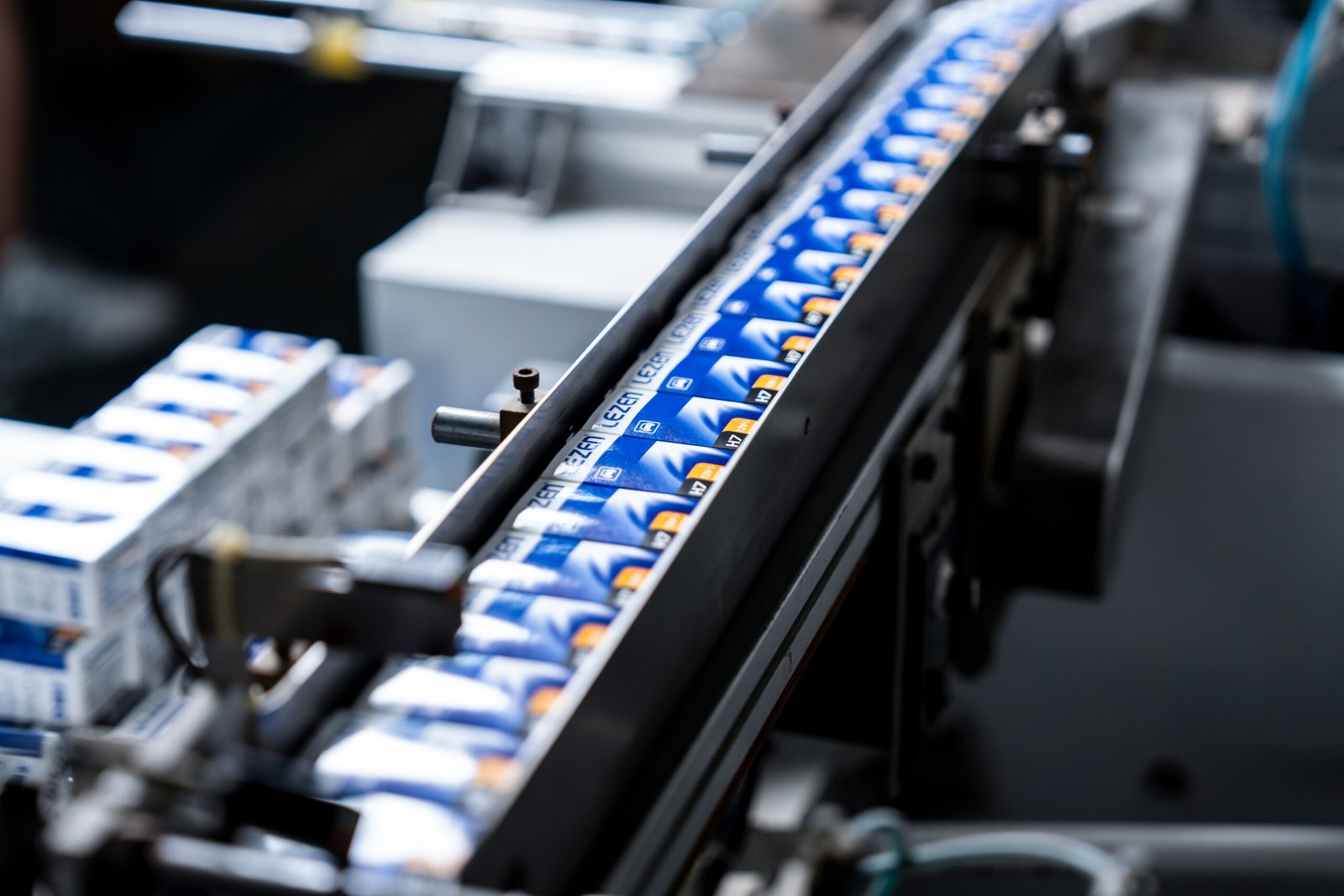

Halogen bulbs are still widely used in the global automotive lighting industry. As market demand grows, producing high-quality halogen bulbs efficiently and consistently becomes a key challenge for manufacturers. As a leading automotive lighting manufacturer, we use advanced automated production lines. These lines improve production efficiency and ensure high-quality bulbs. At the same time, we meet customer needs for bulk orders and customized services.

Learn About the Production Process of Factory Halogen Bulbs Now!

LEZEN Lighting is a leading manufacturer of automotive lighting products, specializing in high-quality halogen bulbs. Since 2010, the company has operated a production facility in Foshan, China, with 16 fully automated production lines, producing 3.6 million halogen bulbs each month. We provide stable supply assurance to global automotive lighting brands and distributors, ensuring every halogen bulb meets strict quality standards for brightness, lifespan, and gas tightness.

To ensure top quality, we use advanced automation in the production process. Every step, from material preparation to final testing, is carefully controlled to meet international standards. Let’s take a closer look at how we manufacture halogen bulbs.

1.Making filament light bulbs

The filament machine is performed by the automated system to making the double filament. The wire is first wound into a very fine primary coil, and this is then wound once more around a second, thicker core. A large amount of wire can thus fit into a very small space.

2.Cutting glass tube

After the glass tube is cut to length, an exhaust tube must be attached to the top. First the top of the tube is heated using gas/oxygen fires. A tungsten carbide wheel folds the softened glass over to form a dome shape containing a small hole.

3.Making the mount

First, the bridge is made by embedding preformed tungsten wires in a small cylindrical quartz rod. The filament is welded to these support wires and welded to the outerlead assembly consisting of the molybdenum sealing foils and outerleads.

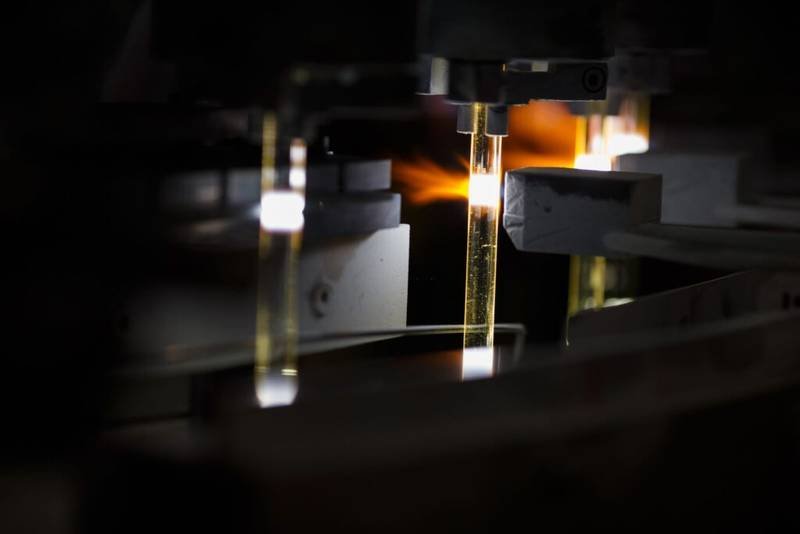

4.Bridge the tungsten wire into cyclindrical quartz rod & Press Sealing

The mount is inserted into the bulb and both parts held securely. The bottom portion of the bulb is then heated to around 3,272°F (1,800°C) using gas/oxygen burners to soften the quartz. Stainless steel press pads, operating at pressures of 20-60 psi, press the quartz to the molybdenum foils forming the hermetic seal. During this operation, the bulb is being flushed with an inert gas (nitrogen or argon) to remove the air and prevent the mount from oxidizing. The outerleads protrude from the end of the press and provide a means to electrically connect the lamp to the lamp base.

5.Evacuating and filling the pressed bulb

The pressed bulb is filled with the halogen gas on the exhaust machine. This machine employs vacuum pumps to evacuate the air from the bulb and a filling system to introduce the halogen gas mixture into the bulb through the exhaust tube. The high internal lamp pressure is achieved by first filling the lamp above atmospheric pressure and then dipping the bulb into liquid nitrogen (-170 °C) which cools and condenses the fill gas below atmospheric pressure. Gas/oxygen fires then melt the exhaust tube at the top of the bulb forming the tip and trapping the gas in the bulb. The gas expands as it warms to the ambient temperature and thus results in a pressurized lamp.

6.Capsule buring and focusing

After the filling process, the lamps are tested for leaks by placing them onto a rotary machine.

7.Capsule Buring # Aging after 72 hours

A random sample is usually taken though some lamps are 100% tested. After the filling process, the lamps are tested for leaks by placing them onto a rotary machine and lighting them for a few minutes. If there is a major leak, the lamp will turn a white yellow color. If there are any major mechanical defects, the lamp will usually arc out.

8.Assembly base and capsule

The base fixed to the jig model are controlled by the vision system information entered to control the movement of the servo motor x,y and z axis unit, and the filament portion of the bulb accurately matches the set value before completing with laser welding. The assembled product is moved to the next process by the conveyor system.

9.Top- coating & marking

The top-coating is made on the surface of the glass tube end of the bulb to inhibit the light of the bulb illuminated from the vehicle’s headlamps directly forward. The product Then the products are moved to marking, which is completed by marking [brand name, part number, specification, date of manufacture, origin, and other customer requirements] on the surface of the BASE using an inkjet printer or laster according to the input value.

10.100% vision #the final inspection

A random sample from each lot is also tested to make sure all specifications (watts, temperature, light output, and life) are met. It applies the most similar environmental conditions to the facility to conduct the lighting test.The examiner will visually screen the appearance. These efforts are meet our customer satisfaction in order to prevent the leakage of even one single defect out of a million.

11.Coating capsule

Finished product without top coating, can coating on surface of glass to change the outlooking color and lighting color. And coating material is imported form Korea. The coating color we could choose dark blue、yellow、golden and so on. We could meet all different meet from our customers.

Why Choose Us

Efficient Production to Meet Large Order Demands

Our production facilities are fully automated, allowing us to quickly fulfill large orders. We also support low minimum order quantities and can handle small batch orders. Whether the order is big or small, we respond quickly and ensure on-time delivery. Our precise equipment and digital monitoring systems ensure each step is completed efficiently and accurately.

Stable Quality Control to Ensure Consistency

We know that product quality and consistency are the foundation of long-term partnerships. Every halogen bulb undergoes strict quality checks during production, including tests for brightness, gas tightness, and vibration. We meet international standards and minimize human errors with precise automation, ensuring each bulb maintains high quality.

Flexible Customization to Meet Your Needs

We offer flexible customization, providing different specifications, color temperatures, and design support based on your requirements. Our team follows your order closely to ensure your unique needs are met and the products match market demand.